About

The factory

The ceramics factory Estrela de Conimbriga is located in the town of Condeixa-a-Nova, in the coastal strip of the central region of Portugal, about 192 km north of Lisbon, 120km south of Porto, and a mere 12 km from Coimbra, the main city of the central region.

Founded in 1975, actually with about 50 employees, the factory has been devoted to the production of Artistic and Decorative Faiance, and to the Utilitarian Tableware of high quality and different decorations.

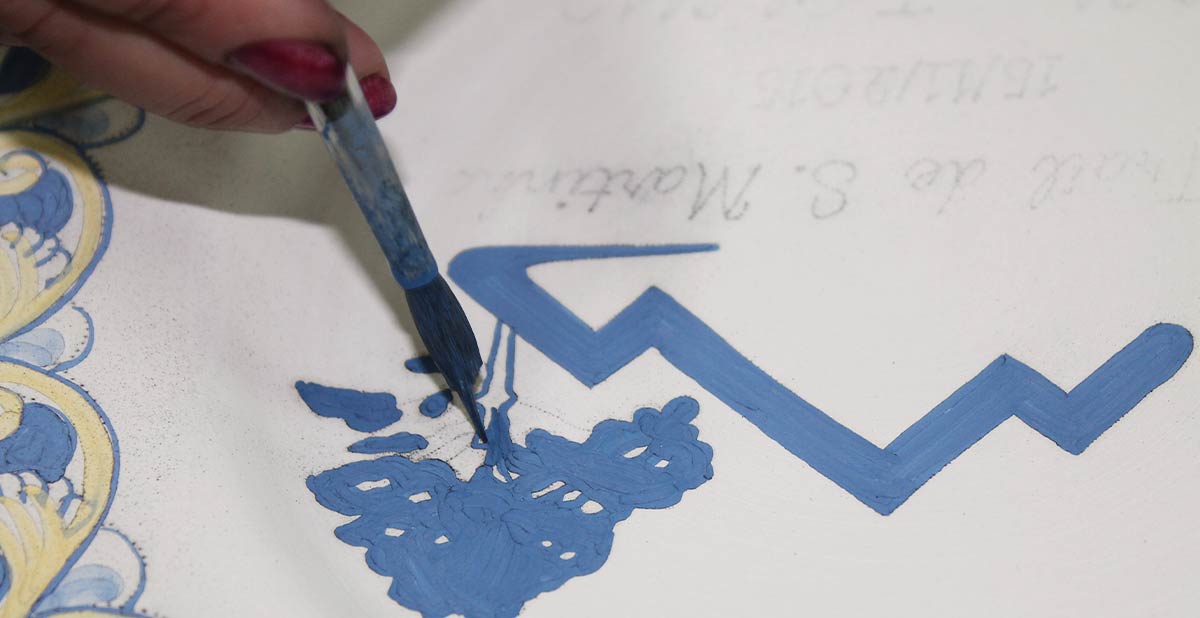

The decorative faiance are inspired on portuguese traditional ceramic of XVII and XVIII centuries and hispano arab, recreated and adapted to our days, keeping the ceramic process of the artisanal, paying special attention to the decoration that is always handmade.

On tableware line, the factory works in strengh collaboration with their clients, in the creation of new models and designs, to meet the consumers needs and market tendency.

Placing their products in may countries like USA, France, Sweden, Switzerland, Spain, Hungary, Bolivia, Japan, Norway and Finland, Estrela de Conimbriga guarantees the quality and innovation of their ceramics, in order to count with client's trust and satisfaction.

Influence

The history of the influence of the Orient in the beginnings of 17th century earthenware is closely linked to the discovery of the maritime route to India, when Vasco da Gama, on the first exploratory journey in 1498, brought back Chinese porcelain for King Manuel. On the second journey, Pedro Alvares Cabral brought back more porcelain for the king. This was the beginning of the creation of a taste. Later, a Portuguese governor of Malacca, Pedro de Faria, ordered a platter in China with his name and the year 1541 inscribed on it in Portuguese. The Chinese potter marked it with the 15th century nien-Ho, undoubtedly as a means of circumventing the imperial decree forbidding exportation. There was, however, a considerable contraband trade, whereby Macau became a major exportation hub at around the time of the end of the Ming dynasty (Sir Harry Farner, Oriental Blue and White).

It was we who expanded the trade of porcelain from China to Europe via the new maritime route, at the time when we basically held the monopoly of Indian Ocean traffic in our hands. It was only on the foundation of the Dutch, British, and finally, French East India Companies in the 17th century that our exclusive dominance was lost. But our 16th century earthenware was naturally the first to attempt to imitate the Chinese porcelain which had enchanted us so much and cost us so dearly…

Later, in 1619, on Philip III of Spain´s visit to Portugal, welcomed with festive bows, that of the Portuguese potters, decorated with the emblems of the respective art, is described by the chronicler Lavanha as featuring, among others symbols of the craft, a potter´s wheel and a porcelain vase made in Lisbon and copied from China, with the following verses at the base:

Here reigns sublime sovereign

Offering you foreign art

Manufactured in the kingdom of Portugal

Which used to be purchased from China at such expense

History

Founding of the company

Founding of the ceramics manufacturer Estrela de Conimbriga in the town of Condeixa-a-Nova

School of training and internationalization

Founding of the Ceramic Training School on the factory premises and the start of exports, mainly to the USA

The international market

Entry into the Scandinavian market

The international market

First customers in Bolivia and Russia

Medal of Merit and the first order for Brazil

Awarded the Medal of Merit – Gold Level by the Municipality of Condeixa-a-Nova and the first order for Brazil

International Trade Fair

Participation at the Index Trade Fair – Dubai

Manufacturing Process

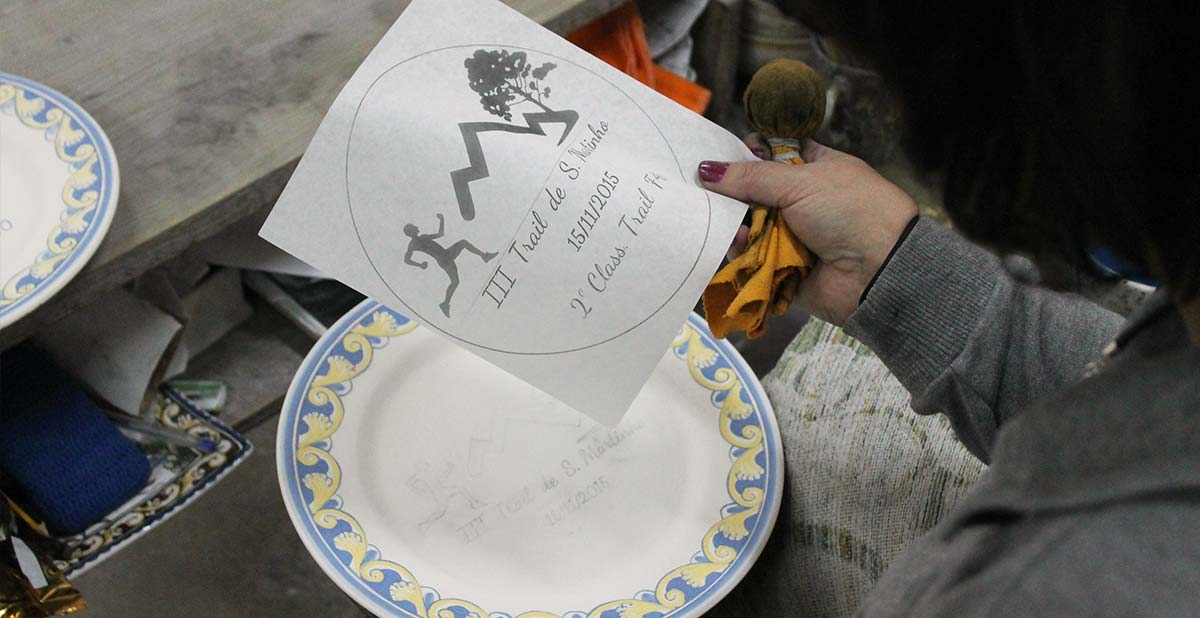

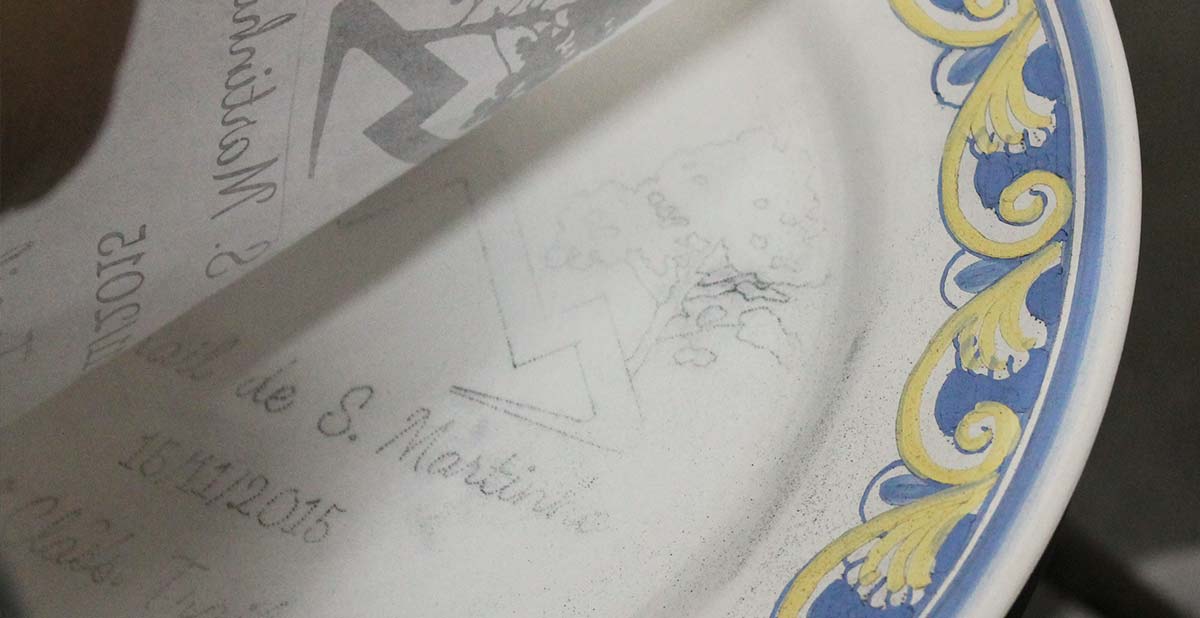

Since the arrival of all materials at the factory until the shipment of the final product to the client, our manufacturing process is mostly handmade.

Our experienced artisans dedicate all attention and care to each piece and the result is a unique product with character and personality.

Learn about our process here, step by step.